Insight Works, a prominent developer of manufacturing and distribution applications for Microsoft Dynamics 365 Business Central, is celebrating a significant milestone as its flagship product, Shop Floor Insight, reaches its 14th anniversary. Launched on June 1, 2010, Shop Floor Insight has grown from its initial release for Microsoft NAV to become an essential Manufacturing Execution System (MES) for manufacturers utilizing Dynamics 365 Business Central. The application's longevity underscores the manufacturing sector's increasing reliance on integrated digital solutions that bridge the gap between shop floor operations and enterprise resource planning systems.

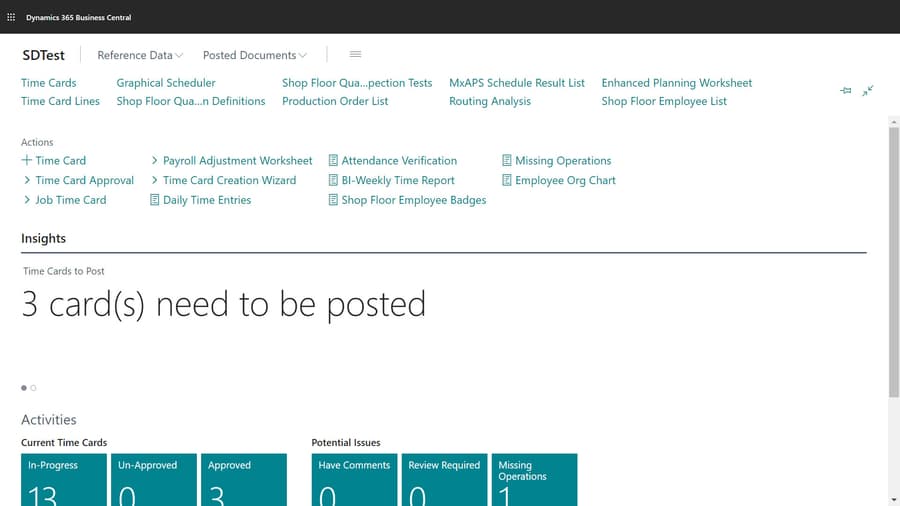

Shop Floor Insight has established itself as a comprehensive MES solution designed to enhance production management through the implementation of advanced barcode technology. The application excels in accurate time capture and employee time management, leveraging scanners, touchscreens, and mobile devices. Its seamless integration with Dynamics 365 Business Central provides manufacturers with real-time insights, flexible configurations, and robust security features, positioning it as a vital tool for modern manufacturing operations. Brian Neufeld, Director of Marketing at Insight Works, expressed enthusiasm about the anniversary, stating the company's ongoing dedication to leveraging barcode technology and integrating advanced features that enable manufacturers to optimize production processes, improve accuracy, and achieve higher quality control standards.

As the highest-rated MES app on AppSource, Shop Floor Insight has earned the trust of professionals across the industry through its comprehensive feature set. The application offers sophisticated time and attendance management, streamlining employee time tracking with capabilities such as mobile tracking, overtime calculations, and exception-based approvals. The efficient data capture system utilizes barcodes and touch screens to simplify labor time tracking and improve user experience, while mobile device compatibility allows employees to capture time and attendance data using smartphones and tablets, providing flexibility and ease of use throughout manufacturing facilities.

Quality and process monitoring represent critical components of Shop Floor Insight's value proposition, enabling manufacturers to capture operational data and manage quality assurance processes effectively. This capability aids in identifying root causes of production issues and improving profit margins through enhanced operational visibility. The real-time reporting and analysis features provide instant insights into job progression, costing, payroll analysis, and offer customizable reporting options that support data-driven decision-making. The application's flexible configuration and integration capabilities include adaptable payroll rules, multi-level approvals, and seamless integration with payroll providers and other enterprise systems, creating a cohesive manufacturing ecosystem.

Enhanced security and authentication measures, including facial recognition, employee badges, and photo capture, ensure accurate tracking and increased security within manufacturing environments. As manufacturing continues to evolve in an increasingly digital landscape, tools like Shop Floor Insight play a crucial role in helping businesses maintain competitiveness through operational excellence. The 14-year journey of Shop Floor Insight reflects broader trends in manufacturing technology adoption and the growing importance of integrated, real-time data management in production environments, positioning the application as a key player in the future of manufacturing execution systems as companies seek to address evolving challenges and opportunities in the sector.